By Juan Carlos Esquivel Bravo

By Juan Carlos Esquivel Bravo

CONTENT

- Introduction

- Background

- Hydroelectric Power Plant Minas San Francisco Description

- Owner Organization

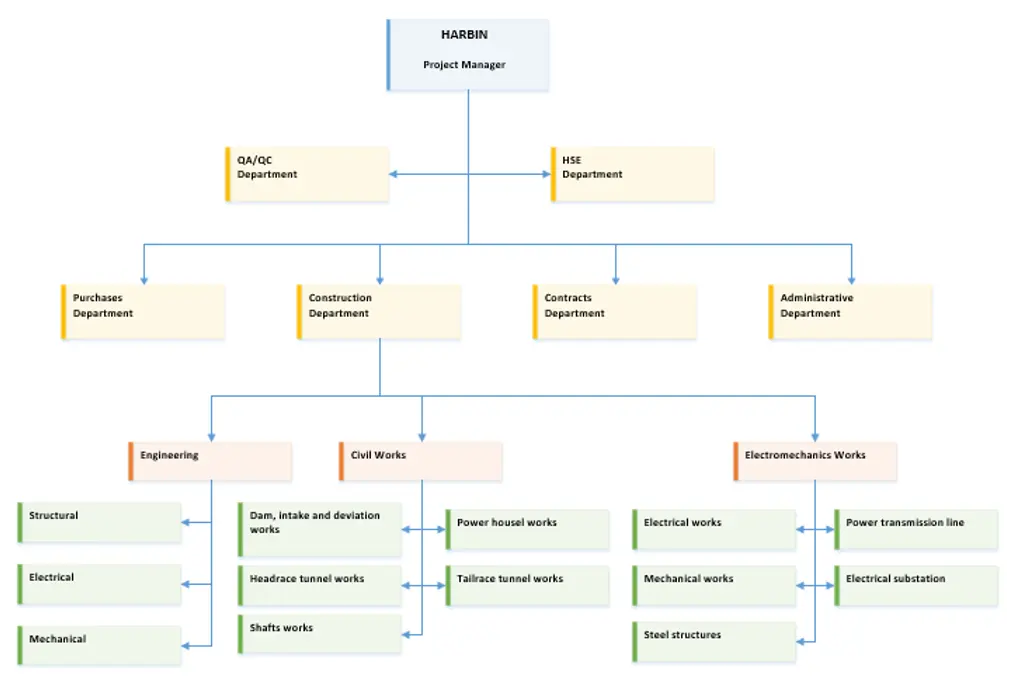

- Main Contractors Organization

- Project Execution

- Conclusions

1. Introduction

From its very definition, it is evident that there are innumerable possibilities for what one can call a project[1]. The same particularity is observed when a categorization of projects is to be made, and it must be adjusted depending on the environment where these projects will be executed.

Therefore, the idea of a large-scale project also differs from one organization to another. However, there is a common agreement about the following aspects:

- Budget much larger than the average project budget within the organization.

- Execution time above one year.

- The number of stakeholders and team members is significantly bigger than the average project within the organization.

Hence, a large-scale project does not fit into the regular structure of an organization, and the question that arises is: How do you control a large-scale project?

To answer this question, we will consider in this article the case of the Hydroelectric Power Plant Minas San Francisco (HPPMSF), which has delivered an annual average[2] of 1040 GWH to the Ecuadorian electric system since its start of operations in 2018.

2. Background

Ecuador is a country located in northwestern South America, bordered by Colombia on the north, Peru on the east and south, and the Pacific Ocean on the west. Over the past two decades, there has been a consistent increase in the electricity demand in the country. In 2017, it was estimated that the county would require 32700 GWH annually by 2023[3].

________________________

1A project is a temporary endeavor undertaken to create a unique product, service, or result. (Project Management Institute, 2017. PMBOK 6th ed.)

2CELEC EP, 2024 – Electricity Generation Data, https://generacioncsr.celec.gob.ec/graficasproduccion/

3Ministry of Electricity and Renewable Energy, 2017 – Electrification Master Plan 2016 – 2025

4 By Addicted04 – Own work with Natural Earth Data, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=16984198

In 2007, the government of Ecuador initiated reforms in the country’s electricity sector. The primary objective of these reforms was to enhance Ecuador’s electricity generation capacity by constructing mainly new hydroelectric power plants. This move was aimed at reducing the country’s dependence on fossil fuels to generate power and satisfy the increasing demand for electricity across the nation.

In 2010, the public company “Corporation Eléctrica del Ecuador – CELEC EP” was established to become responsible for generating, transmitting, and distributing electricity throughout Ecuador. One of the major projects it managed during the 2010s was the HPPMSF, which started construction in 2012 and operation in 2018.

In 2023, Ecuador generated approximately 31500 GWH of electricity[5], with 79% of it coming from hydroelectric power plants. This means that the majority of the electricity supply in the country relies now on hydroelectric power. This is different from the situation in 2012, when a total of 19080 GWH of electricity[6] was generated, with only 62% coming from hydroelectric power plants.

3. Hydroelectric Power Plant Minas San Francisco Description

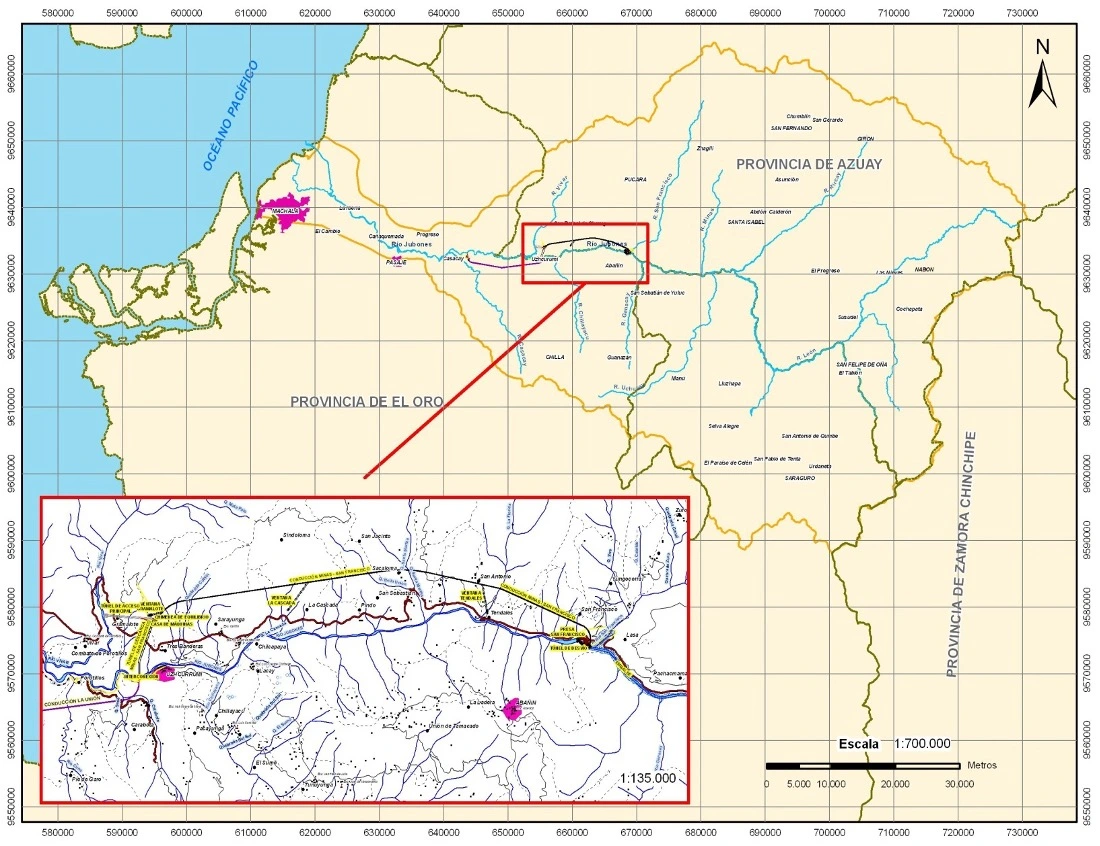

The HPPMSF is located in the southern region of Ecuador across the provinces of Azuay, El Oro, and Loja. It uses the waters of the Jubones River which flows towards the Pacific Ocean.

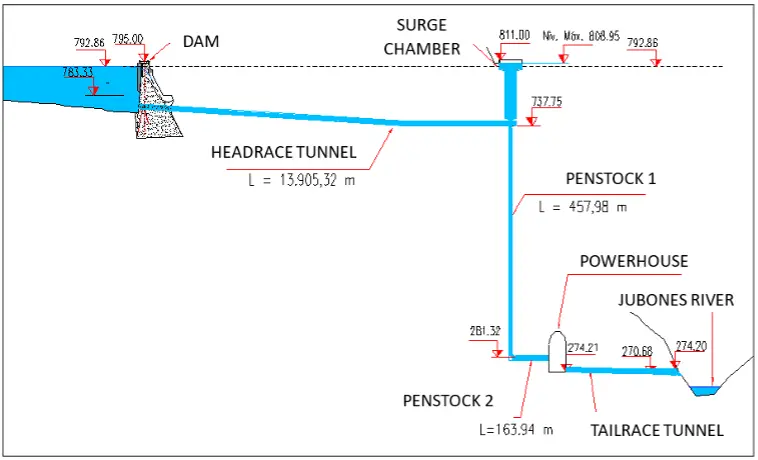

The HPPMSF is a power generation system composed of multiple elements, with the main ones being[7]:

- Dam – gravity type from rolled concrete, height = 80 m.

- Reservoir – capacity = 14 million m3, length = 5 km.

______________________________________________

5 CENACE, 2023. Annual Operating Report. https://www.cenace.gob.ec/wp-content/uploads/downloads/2024/03/Informe-Operativo-2023_vf.pdf

6 CONELEC, 2012 – Electrification Master Plan 2013 – 2023

7 CELEC EP, 2024 – https://www.celec.gob.ec/celecsur/informacion-tecnica/central-hidroelectrica-minas-san-francisco/

- Headrace tunnel – length = 13.9 km, cross-section = 20 m2.

- Surge chamber – underground structure, height = 68 m, diameter = 16 m

- Penstock – underground steel pipe, total length = 620 m, length vertical segment = 458 m, length horizontal segment = 164 m, diameter = 3.8 m

- Powerhouse – underground structure with 3 Pelton turbines installed, nominal power of 90MV each.

- Tailrace tunnel – length = 1.6 km, cross-section = 45 m2.

- Power transmission line – length 42 km.

Figure 3. Schematic HPPMSF 5CELEC EP, 2014)

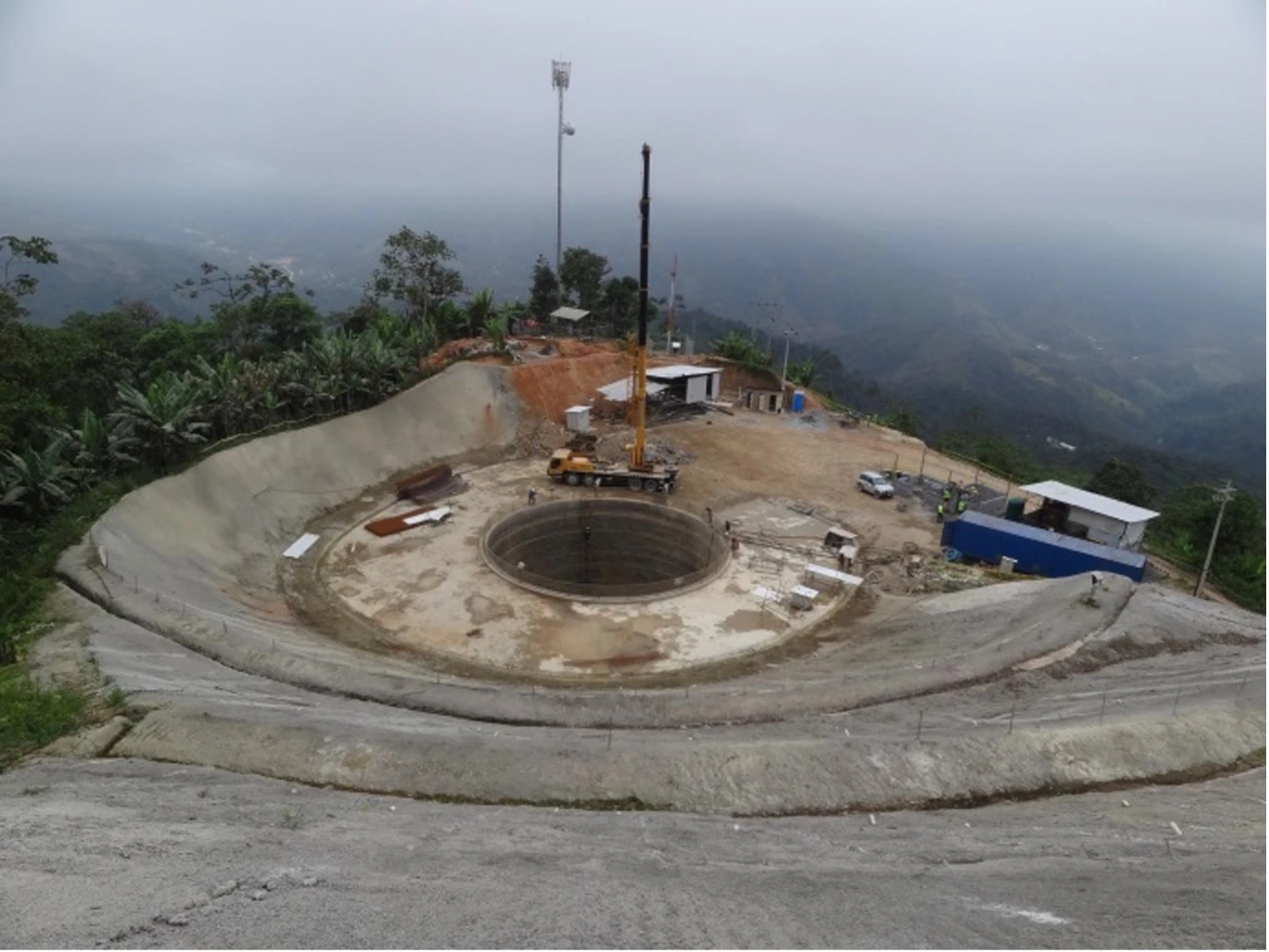

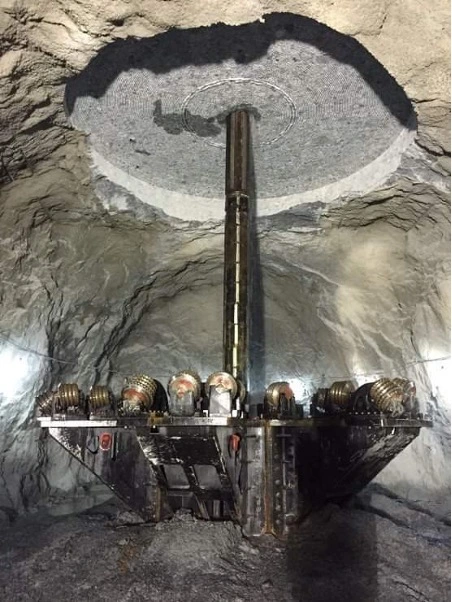

The HPPMSF was built over a span of six years, beginning in 2012, and its budget was c.a. 560 million USD[8]. During the peak of the work, around 2500 people were employed. This included technical and administrative staff, as well as workers. Additionally, the construction required various temporary facilities and structures, along with specialized equipment, including a custom-made tunnel boring machine and two raise boring machines.

_______________________________________________

8. Ministry of Energy and Mines, 2018. https://www.recursosyenergia.gob.ec/wp-content/uploads/2018/10/GprMSF.pdf

Picture 1. Dam and reservoir (CELEC EP, 2022)

Picture 2. TBM for headrace tunnel (HIDROJUBONES, 2014)

Picture 3. Concrete factory TBM (HIDROJUBONES, 2014)

Picture 4. Surge chamber (HIDROJUBONES, 2013)

Picture 5. Raise boring machine, Penstock (CELEC EP, 2014)

Picture 6. Powerhouse (CELEC EP, 2019)

Picture 7. Electrical Substation (CELEC EP, 2019)

Picture 8. Offices & barracks HARBIN (HINDORJUBONES, 2014)

During the construction of HPPMSF, several other works were carried out in the area, but they are not mentioned in this document.

4. Owner Organization

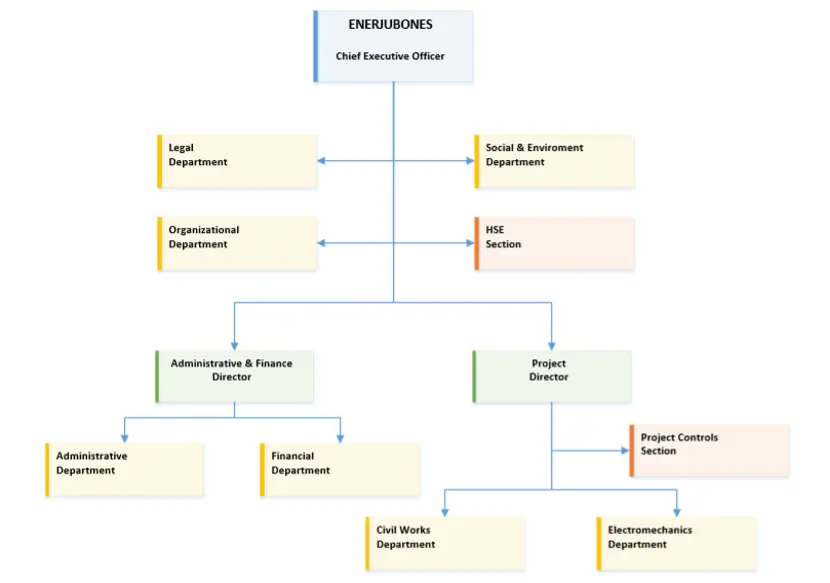

In 2011, CELEC EP obtained the rights to the HPPMSF and completed all the necessary steps for its construction and later operation. To manage this, CELEC EP created a dedicated business unit called ENERJUBONES. This unit was active from 2011 to 2020, and its original organizational structure is displayed in Figure 4.

Figure 4. Organigram Business Unit ENERJUBONES (CELEC EP, 2014)[9]

ENERJUBONES committed to adhering to good practices in project management since its beginning. To achieve this, all staff members received training in the guidelines, processes, methodologies, and best practices of the Project Management Institute (PMI). Furthermore, in 2015, ENERJUBONES established an internal Project Management Office (PMO) to facilitate adherence to these practices.

The Chief Executive Officer served as the sponsor[10] for all the projects around the HPPMSF. He was also the point of contact for superior entities, such as CELEP EP and other government entities.

_________________________________________________

[9] Comptroller General Office, 2015. https://www.contraloria.gob.ec/WFDescarga.aspx?id=43883&tipo=inf

[10] Project Management Institute, 2017. PMBOK Guide (6th ed)

The Project Director managed the construction of the HPPMSF and coordinated additional and complementary projects.

The Civil Works and Electromechanics Departments formed a technical team, which ensured compliance with technical specifications and oversaw on-site activities depending on the projects.

The Project Controls Section tracked, reviewed, and reported the overall progress of the projects. This section managed the project information system.

The Social and Environment Department together with the HSE section oversaw local stakeholders in the influence area of the HPPMSF and managed the Health, Security, and Environment aspects around the projects and internally in ENERJUBONES

When required, other departments supported projects in their area of expertise while handling the daily operations of the business unit.

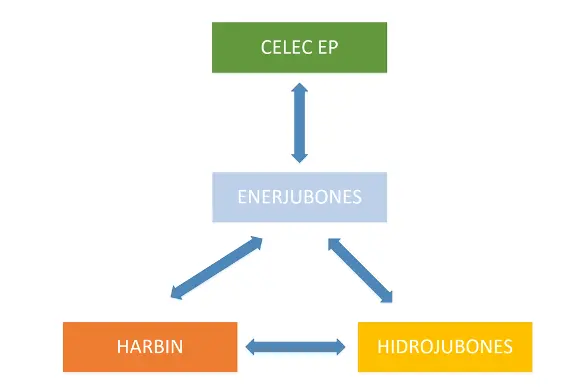

The construction of the HPPMSF involved 2 main contracts:

An EPC contract worth approximately 477 million USD[11] was awarded to HARBIN ELECTRICAL INTERNATIONAL CO LTDA for the construction of the project.

A consultancy services contract worth approximately 30 million USD[11] was awarded to the joint venture CONSORCIO HIDROJUBONES, formed by the companies CAMINOSCA SA, ASTEC CIA LTDA, INTEGRAL SA, and GAS NATURAL FENOSA ENGINEERING SLU, for the supervision of the construction.

The project Director acted as a contract manager for both contracts supported by the Legal Department.

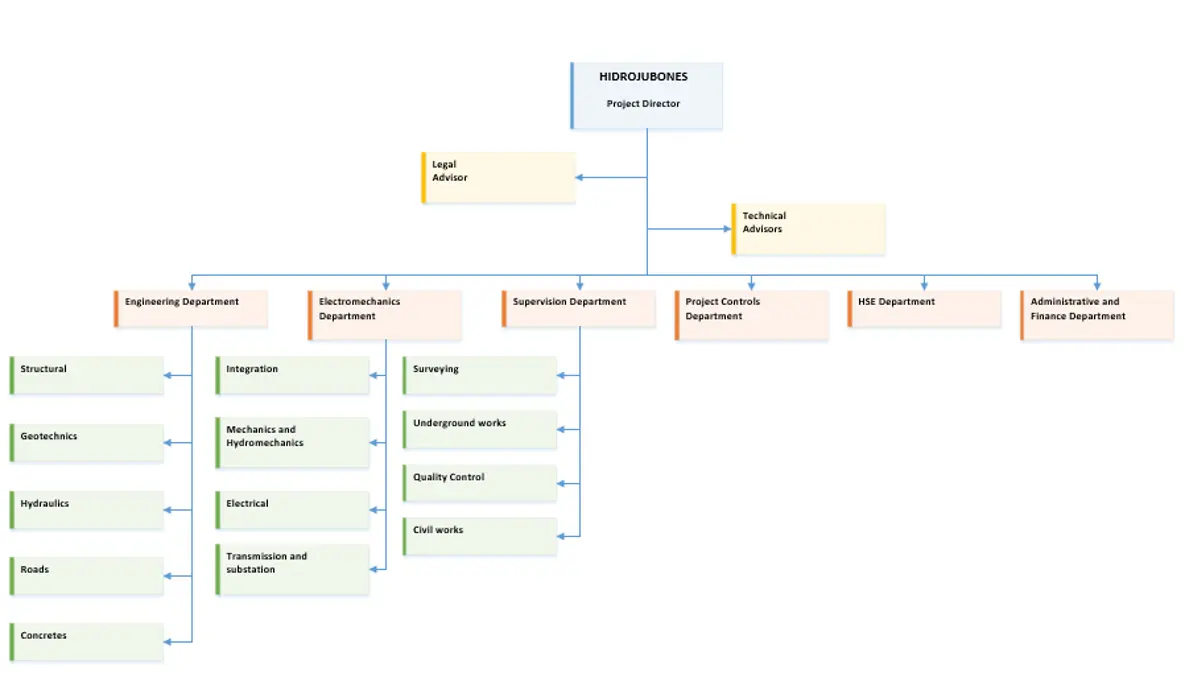

The organizational structure of the supervisor consultant, CONSORCIO HIDROJUBONES, is shown in Figure 6.

Figure 6. Organigram Consultant, HIDROJUBONES (CELEC EP, 2012)

6. Project Execution

Before starting the construction work, ENERJUBONES obtained all the necessary permits from the government and acquired the required land for the project. In addition, they established a contact center to keep the area’s residents informed about the project and to manage their expectations regarding future employment opportunities and community projects that could be implemented as a compensation measurement.

In addition, ENERJUBONES located reliable sources of raw materials for the construction and improved the electricity system in the region to ensure its capacity and reliability for the construction work.

At the start of construction, HARBIN built various facilities including concrete factories, on-site offices, and worker barracks. ENERJUBONES directly supervised these works. After HARBIN began working on other tasks, HIDROJUBONES took over supervision tasks.

Throughout the construction process, HARBIN was responsible for managing all project work, while HIDROJUBONES oversaw the work to ensure it adhered to the most recently approved engineering plans. HIDROJUBONES reported to ENERJUBONES regarding the status of the project, including performance against baseline targets for all components, quality control measures, and any identified non-conformities as well as risks, where special attention was paid to critical activities which were continuously tracked.

HARBIN was also in charge of the construction engineering based on CELEC EP’s design. HIDROJUBONES reviewed and approved the results. ENERJUBONES was responsible for the project change procedure, and any proposed changes could be made by HARBIN or HIDROJUBONES. CELEC EP would then approve or reject those proposed changes. When disputes arose between HARBIN and HIDROJUBONES, ENERJUBONES intervened to solve them.

The graphic below indicates how the different actors interacted during the construction.

Figure 7. Project interactions HPPMSF

7. Conclusions

This article aims to provide insight into how to control a large-scale project and the discussed example shows us that a large-scale project requires an exclusive dedicated organization, which most of the time must be created from scratch. This could be the case for all involved entities such as project owners, contractors, or consultants.

Creating a specific organization allows using recognized project management processes and techniques from the beginning. Moreover, it also allows tailoring these processes to the specific requirements of the project.

The participants in a large-scale project can have different organizational structures without affecting the well-functioning of the project.

8. References

Comptroller General Office, 2015. Special examination Hydroelectric Project Minas San Francisco

CELEC EP, 2024. Electricity Generation Data

CELEC EP, 2024. Technical data Power Plant Minas San Francisco

CENACE, 2023. Annual Operating Report

CONELEC, 2012. Electrification Master Plan 2013 – 2023

Ministry of Electricity and Renewable Energy, 2017. Electrification Master Plan 2016 – 2025

Ministry of Energy and Mines, 2018. Progress reports Hydroelectric Project Minas San Francisco

Project Management Institute, 2017. PMBOK 6th ed.

By Juan Carlos Esquivel Bravo

Recent Comments