For major capital expenditure projects, every day late equates to thousands of dollars lost. In fact, for

an average size project, even a 10 percent overrun can lead to a $5 million hit to project profitability.

Extrapolate this out to the average 20 percent to 30 percent delay that most projects report and you

are looking at a significant loss—one that impacts your company’s bottom line.

In this white paper, we explore the true cost of project delay, from profitability to company reputation,

and arm you with the solutions you need to avoid and overcome overruns.

The Probability of Delays and Cost Overruns on Today’s Projects

You may think that the effects of an unsuccessful project are only felt on an individual project level. But

the truth is, project delays and overruns are felt across the entire company. This causes a ripple effect

from the Executive Team to hands-on engineers, and from bottom line cash flow to follow-on customer

work (which can ultimately impact future employment).

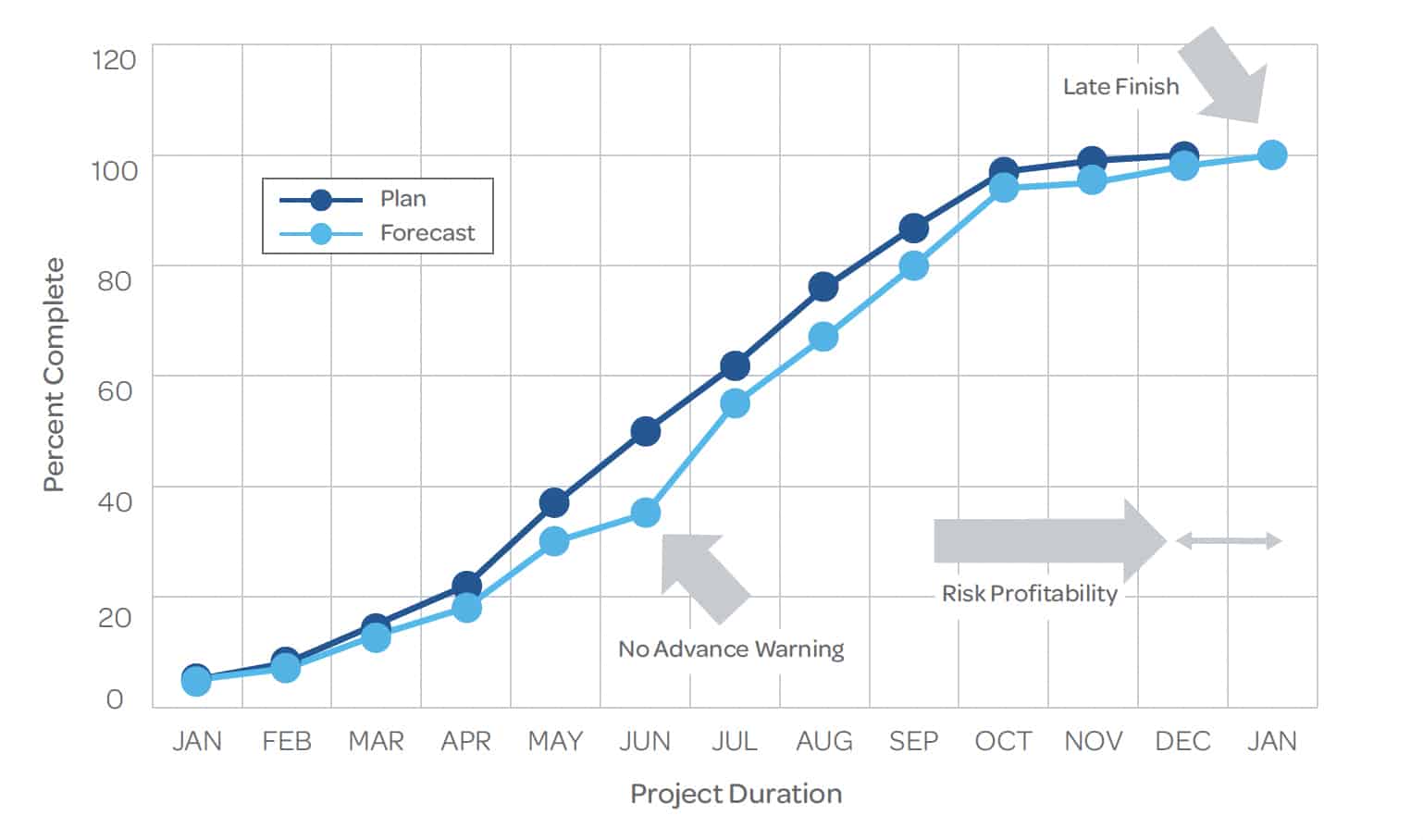

According to research done by the Construction Industry Institute (See Figure 1), projects typically

begin on track; however, one major widespread event can throw the entire project off course and project

teams are never fully able to recover. Why? It’s far easier to start work than to finish work, especially when

that work is complicated. And the reality is that most forecasts aren’t very reliable. Once a widespread

event occurs, it becomes nearly impossible to make up for a problem in the next month, so the delays

will inevitably continue.

These continued time delays directly equate to cost overruns. Take for example, a project that has

a contract value of $50 million with a duration of three years. That breaks down to a value per day of

$45,662. Account for an average project delay of 30 percent and the average cost of delay is just shy of

$15 million. Imagine telling your customer that their $50 million project is actually going to cost $65 million.

You better be prepared to answer some tough questions on how and where those costs are going to

be recovered.

What is truly painful for project teams is when the cost overruns continue on after the project was

originally supposed to finish. This means you are spending money against a baseline that showed it should

have finished months ago. At that point, it is physically impossible to catch up, as there is no mitigation

plan available for a project that is already supposed to be complete.

The Main Causes of Project Delay

While there are dozens of individual reasons a project can be delayed, the root causes can be summarized

into three major categories:

1. Separation of people by organizational boundaries. If you’re in a very small company where everyone

can be in the same building or room on a daily basis, this issue may not be as significant. However the

majority of business are spread out across multiple sub-organizations and facilities, and often across

state—and even country—lines. As far as electronic communication has come in the past two decades,

it can still be difficult to communicate across disparate locations. Communication lines are thinner

and slower, and you run the risk of things getting “lost in translation.”

2. Differences in process. Most organizations have multiple stakeholders involved in a single project—

from service centers, engineering and procurement, to project control teams and/or subcontractors.

Each of these individual stakeholder teams can follow different processes, making it difficult to piece

together a comprehensive view of project status in real-time.

3. Multiple technologies. Not only do organizations face the challenge of multiple groups and disparate

organizational boundaries, but each of these teams can also use different tools to perform their

day-to-day work. With different data export features and reporting capabilities, project controls

specialists may find themselves trying to integrate apples and oranges in order to report on current

project status.

For mid- to large-sized companies, under normal circumstances obtaining a current status on a single

project can take up to four weeks. Why? Thanks to the challenges outlined above, a project manager has

to spend countless hours chasing people down, piecing together individual spreadsheets and emails in

different formats and following up on incomplete or late information—in any given month. And by the time

they are finished with one month, it’s already time to start the process over again for the next statusing!

The problem is compounded when you realize that by the time the decision makers receive current

project status, it’s already outdated, and can be too late to catch a delay or cost overrun. Think about

driving a car. Imagine if when someone swerved into your lane, you had to wait a full four seconds before

you could do anything. It would be a disaster every single time. You need to be able to react right away…

the same goes for projects.

Getting a Slipped Project Back on Track

So your project has gone off the rails—now what? You have two main options: get back on schedule or be late. The choice, however,

isn’t as straightforward as it seems. Getting back on schedule may require you to increase resources, cut scope, sacrifice quality and/or

approve changes. On the other hand, being late can result in an unhappy client, having to pay liquidated damages, receiving less repeat

task orders and/or subcontractor dispute. And while every project team would ideally like to get back on schedule, sometimes being late

is less expensive and more viable, despite its bad nature.

The key is in getting the plan together the right way in the first place, so that you are not in a position to have to make either one of

these choices.

A Sound Schedule is the Key to Project Success

So how do you get the plan right in the first place? Consistent project success starts with having a solid schedule foundation. Deltek

Acumen Fuse® can help you diagnose and resolve schedule shortcomings in a matter of minutes to make sure you start—and end your

project—on the right foot. With its advanced analytics, schedule shortcomings are quickly and easily identified; its built-in schedule

cleanser immediately corrects identified issues; and the tool’s flexible reporting options enable you to communicate to all key

stakeholders what they need to know about your project in real-time.

When combined with Deltek Acumen Risk, you can also effectively account for and proactively reduce risk exposure for an accurate

forecast you can rely on. How? Straightforward analysis eliminates the statistical and logical complexities of building risk models;

user-friendly reports provide insight into key risk drivers and high-risk areas of the schedule allowing for targeted mitigation efforts; and a

powerful Monte Carlo engine ensures the utmost accuracy and unrivaled analysis performance.

Recent Comments